Columbia University research study explores digital cooking using lasers and 3D printing

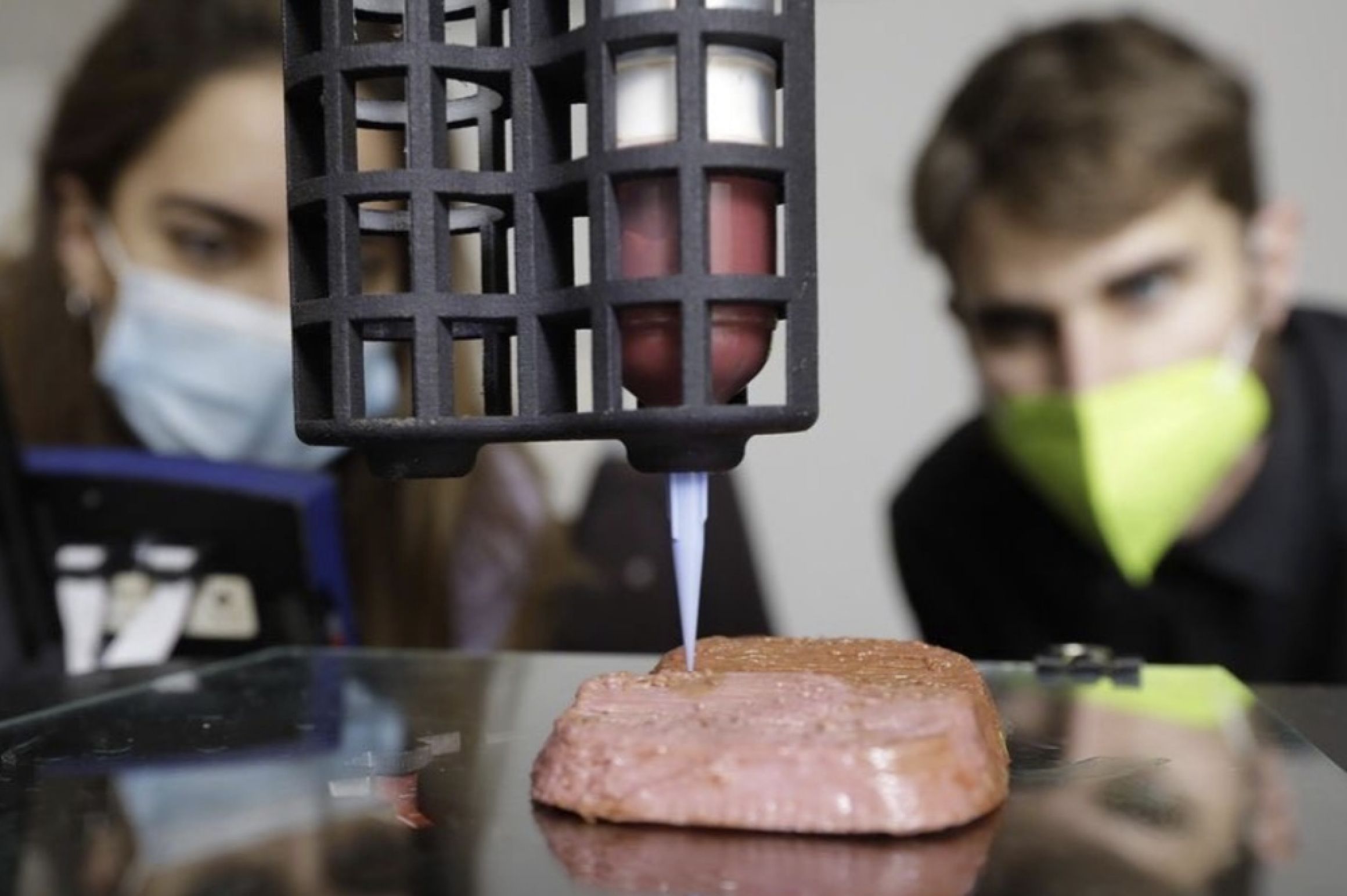

Engineers at Columbia University have announced their latest digital project which involves using lasers for cooking and 3D printing for assembling foods, to create a fully automated personal chef.

The research is part of Columbia’s Creative Machines Lab, an initiative that builds autonomous robotics and comprises of researchers from disciplines of engineering, computer science, physics, maths and biology.

Headed by Hod Lipson, Professor Mechanical Engineering, the “digital food” team has been developing 3D-printed foods since 2007. Yet more recently, the team of engineers have also incorporated the use of lasers to create food products specified exactly to consumer preference by controlling the nutritional profile, flavour and texture.

Lipson’s team have been testing lasers by cooking chicken using blue and infrared light and outlined their work in a study published this month.

The study compared variables including cooking depth, colour development, moisture retention and flavour differences between laser-cooked and stove-cooked meat.

Rendering of a digital cooking appliance that uses several ingredients and a precise cooking laser to assemble and cook meals using digital recipe. Picture courtesy of Columbia University

Rendering of a digital cooking appliance that uses several ingredients and a precise cooking laser to assemble and cook meals using digital recipe. Picture courtesy of Columbia University

The findings found that laser-cooked meat shrinks 50% less than meat cooked on a stove, whilst retaining double the moisture content and flavour.

PhD student at Hod Lipson’s Lab, Jonathan Blutinger, who leads the project said: “Cooking is essential for nutrition, flavor, and texture development in many foods, and we wondered if we could develop a method with lasers to precisely control these attributes.

“In fact, our two blind taste-testers preferred laser-cooked meat to the conventionally cooked samples, which shows promise for this burgeoning technology.”

Despite the positive results of laser-cooking, Professor Lipson highlighted the limitations of the project such as the lack of a sustainable ecosystem to support it. He commented: “What we still don’t have is what we call ‘Food CAD,’ sort of the Photoshop of food. We need a high level software that enables people who are not programmers or software developers to design the foods they want. And then we need a place where people can share digital recipes, like we share music.”