BioBetter raises $10M to scale development of cell growth factors made from tobacco plants for cultured meat production

Image courtesy of BioBetter

Israeli start-up BioBetter has secured $10M in a Series A funding round, to further improve and commercialise its cell growth factors (GFs) made from tobacco plants.

Some of the funding raised will be used to develop BioBetter’s product portfolio of growth factors. It will also be used to recruit new employees as the company aims to double its workforce.

Additionally, the start-up has plans to expand production by moving to a larger pilot plant at the Tel Hai Industrial Park in northern Israel. BioBetter says the new site will allow it to increase its tobacco plant processing capacity, and meet growing demand for GFs in the cellular agriculture sector.

The funding round was led by Jerusalem Venture Partners, with other funds coming from Milk and Honey Ventures, and the Israeli Innovation Authority.

BioBetter is one of several foodtech start-ups that are part of the Margalit Start-up City Galil innovation centre, which was launched last year by Erel Margalit, Founder and Executive chairman of Jerusalem Venture Partners.

“BioBetter has the key to scale up production of cultivated meat, make it accessible to consumers globally and protect our planet,” said Margalit. “This is not only because of the sheer volumes of GFs it can produce, but also by virtue of its ability to substantially reduce their cost.”

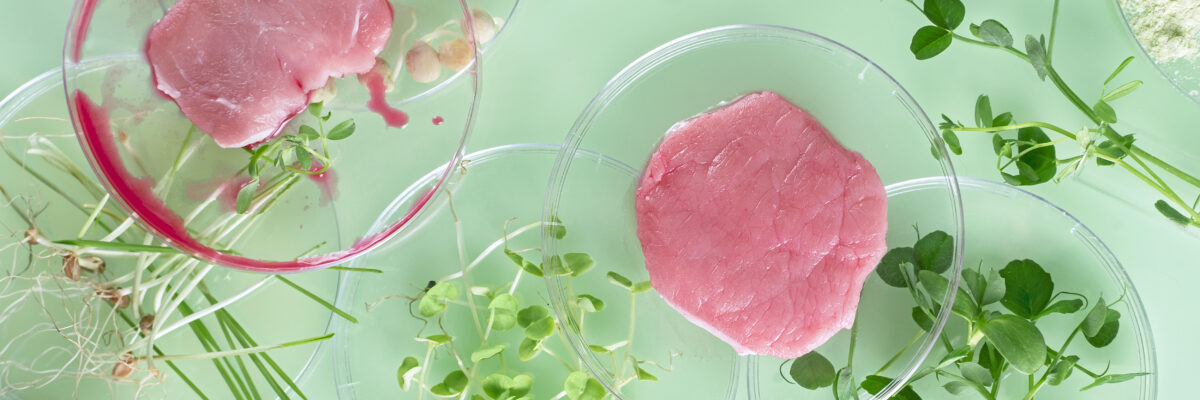

Growth factors are necessary in the production of cultured meat, as they allow cells to multiply. They can also be used in pharmaceutical and cosmetic applications.

The start-up’s GFs are cruelty-free, as no foetal bovine serum (FBS) or animal ingredients are used in its formulation.

To create the plant-based alternative to insulin, FGF2, and transferrin from animals, or the equally costly fermentation of yeast or bacteria, all of which are used in GFs, the company identifies and optimises the target protein, clones its gene into BioBetter expression vectors and then transfers it into the tobacco plant. The plant then produces the protein.

By developing them from tobacco plants, these growth factors can be much more economical for lab-grown meat start-ups, as production costs could be reduced by 300% according to BioBetter.

The growth factor FGF2, for instance, can cost anything between $50,000 to $500,000, depending on the amount, whereas the start-up says its technology can bring costs down to just one US dollar per gram.

“World population growth, combined with dwindling natural resources, are going to put incredible strain on meat supply – and the already fragile environment – in the coming decades,” said Amit Yaari PhD, CEO of BioBetter.

“Cultivated meat offers a promising solution to these problems and can ensure a more resilient supply chain with better economic and environmental returns.”

Dana Yarden, Managing Director and Co-Founder of BioBetter added: “Thanks to the BioBetter platform, tobacco is set to make a pivotal comeback as a catalyst for bringing better food security.

“As a result of this funding round, we can scale up production in 2023 and expect to go commercial with our tobacco plant-derived, food-grade GF portfolio by 2024.”

Should the food industry prioritise factory-based meat production to tackle environmental collapse? Find out in this Food Matters Live Podcast episode with George Monbiot: